|

|

|

|

|

|

|

| Industrial Design |

Plastic Engineering | Rapid Prototyping |

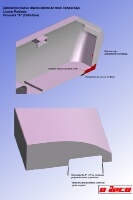

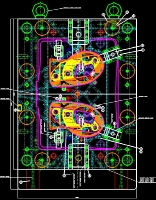

Mould Design |

Manufacture Moulds |

Plastic Production |

A Versatil and Effective Solution |

| ARAW TECNO

COMERCIAL S.L. (ARTECO) |

| Three services making up a complete

cycle |

| To provide

a global service, ARTECO has established a vertical relationship

with the intention of covering the upstream stages for products

which are predominantly made of plastic. Working together with ARTE,

a leading plastic injection mould and die manufacturer. Despite the fact that the three firms still operate independently, together the companies offer "turnkey" solutions, right the way through from the conceptualization of an object to the delivery of an initial run, with guaranteed quality throughout and minimizing the information loss that normally derives through three independent efforts. Such is our understanding of what a global project should do: link together the stages of a project which normally have somewhat ambiguous boundaries and thus offer a single solution, aimed at safeguarding our clients from management problems. ARTECO was founded to satisfy a need that had been detected by ARTE: to fill the gap between the industrial design and construction of a mould. To such ends, the ARTECO technical team, specialists in developing projects for plastic injection parts, develops the product engineering and provides solutions which facilitate the construction of the mould and optimize production runs. ARTECO employs advanced technology such as rapid prototypìng to achieve its goals. Arteco-Arte has leading edge production resources with a total of 14 work stations (CAD-CAM) and latest generation production equipment comprising machine centres, wire and electrospark erosion units, etc.. ARTE's exactingness, technique and experience in the construction of moulds stand as a guarantee to this new engineering service. The coordination of the work between the two firms guarantees efficiency and, as a member of ASCAMM it is able to supply moulds with official approval certification. |

|

Below

is a listing of just some of the companies we work with:

|

|

Airtecma, Alcatel, Audi, Avellanet, Balay,

Casals, Citroën, Dynamit, Ford, Frape Behr,

Hitachi, Hewlett, Packard, Honda, Iberfashon, Mai, Mery,

Movilfrit, Peguform, Peugeot, Philips, Renault, Rocal, Seat,

Sony, Telesincro, Trilla, Valeo, Volkswagen, etc. |